- By medium

- By subject

- By budget

- Sales

- Gift cards

- Discover all art

- Artists

- Editors’ picks

- Ideas

Artwork description:

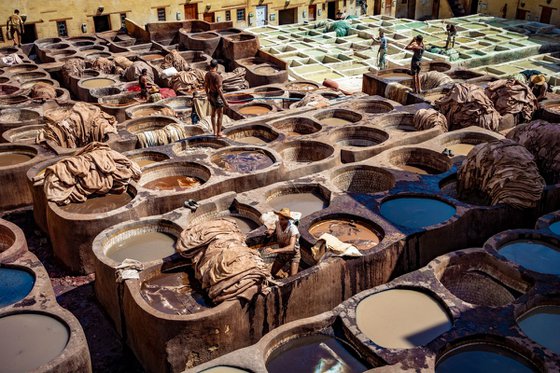

The city of Fes - Morocco's third largest city – was founded in the 8th century and it has a distinct traditional character. Located behind a high wall, in the car-free alleys of the old town or medina where hundreds of merchants and craftsmen sell a range of products are several tanneries which are almost a thousand years old.

Fes’ tanneries are composed of numerous stone vessels filled with a vast range of dyes and various liquids spread out like a tray of watercolors. Dozens of men, many standing waist deep in dyes, work under the hot sun tending to the hides that remain soaked in the vessels. The tanneries process the hides of cows, sheep, goats and camels, turning them into high-quality leather products such as bags, coats, shoes, and slippers. This is all achieved manually, without the need for modern machinery, and the process has barely changed since medieval times.

Hides are first soaked in a mixture of cow urine, quicklime, water, and salt. This caustic mixture helps to break down the tough leather, loosen excess fat, flesh, and hair that remain on them. The hides are soaked for two to three days after which tanners scrap away excess hair fibres and fat in order to prepare the hides for dyeing. The hides are then soaked in a mixture of water and pigeon poop. Pigeon poop contains ammonia that acts as softening agents that allow the hides to become malleable so they can absorb the dye. The tanner uses his bare feet to knead the hides for up to three hours to achieve the desired softness.

The hides are then placed in dying pits containing natural vegetable dyes, such as poppy flower (red), indigo (blue), henna (orange), cedarwood (brown), mint (green), and saffron (yellow). Other materials used for dyeing include pomegranate powder, which is rubbed on the hides to turn them yellow, and olive oil, which will make them shiny.

Once the leather is dyed it is taken out to dry under the sun. The finished leather is then sold to other craftsmen who make the famous Moroccan slippers, as well as wallets, handbags, furniture and other leather accessories.

From a Limited Edition of 12 + 3 Artist's Proof

- Signed Certificate of Authenticity with Edition Number.

- Printed on Hahnemühle FineArt Pearl paper (285 g/m²) with a special coating to ensure a classy, pearly shine. This luxurious gallery standard paper's intense whiteness displays impressive contrasts and pictorial depth.

-Very water and humidity resistant

- 100-year luminosity

- The gallery standard print comes rolled inside a hard tube

protected with bubble wrap and acid free paper and shipped in a cardboard box.

This Artwork is available as:

120 x 80cm (Limited Edition of 12 + 2AP's)

100 x 66cm (Limited Edition of 25)

Ready to hang framed print or mounted on Alu-Dibond base sealed under acrylic glass is also available, contact Artfinder for details and price

*NOTE - All images used are an approximate scale for illustrative purposes and individual artwork scale may differ. Always check the artwork dimensions and measure your room carefully.

Materials used:

Hahnemühle FineArt Pearl paper (285 g/m²)

Tags:

#abstract #colourful #pastel #pattern #photography #architecture #fine art #people #geometry #documentaryWatercolour 3 (2016) Photograph

by Serge Horta

6 Artist Reviews

£1,224.16

- Photograph on Paper

- From a limited edition of 12

- Size: 120 x 80 x 0.5cm (unframed) / 122 x 82cm (actual image size)

- Signed and numbered certificate of authenticity

- Style: Photorealistic

- Subject: Abstract and non-figurative

Loading

Artwork description

The city of Fes - Morocco's third largest city – was founded in the 8th century and it has a distinct traditional character. Located behind a high wall, in the car-free alleys of the old town or medina where hundreds of merchants and craftsmen sell a range of products are several tanneries which are almost a thousand years old.

Fes’ tanneries are composed of numerous stone vessels filled with a vast range of dyes and various liquids spread out like a tray of watercolors. Dozens of men, many standing waist deep in dyes, work under the hot sun tending to the hides that remain soaked in the vessels. The tanneries process the hides of cows, sheep, goats and camels, turning them into high-quality leather products such as bags, coats, shoes, and slippers. This is all achieved manually, without the need for modern machinery, and the process has barely changed since medieval times.

Hides are first soaked in a mixture of cow urine, quicklime, water, and salt. This caustic mixture helps to break down the tough leather, loosen excess fat, flesh, and hair that remain on them. The hides are soaked for two to three days after which tanners scrap away excess hair fibres and fat in order to prepare the hides for dyeing. The hides are then soaked in a mixture of water and pigeon poop. Pigeon poop contains ammonia that acts as softening agents that allow the hides to become malleable so they can absorb the dye. The tanner uses his bare feet to knead the hides for up to three hours to achieve the desired softness.

The hides are then placed in dying pits containing natural vegetable dyes, such as poppy flower (red), indigo (blue), henna (orange), cedarwood (brown), mint (green), and saffron (yellow). Other materials used for dyeing include pomegranate powder, which is rubbed on the hides to turn them yellow, and olive oil, which will make them shiny.

Once the leather is dyed it is taken out to dry under the sun. The finished leather is then sold to other craftsmen who make the famous Moroccan slippers, as well as wallets, handbags, furniture and other leather accessories.

From a Limited Edition of 12 + 3 Artist's Proof

- Signed Certificate of Authenticity with Edition Number.

- Printed on Hahnemühle FineArt Pearl paper (285 g/m²) with a special coating to ensure a classy, pearly shine. This luxurious gallery standard paper's intense whiteness displays impressive contrasts and pictorial depth.

-Very water and humidity resistant

- 100-year luminosity

- The gallery standard print comes rolled inside a hard tube

protected with bubble wrap and acid free paper and shipped in a cardboard box.

This Artwork is available as:

120 x 80cm (Limited Edition of 12 + 2AP's)

100 x 66cm (Limited Edition of 25)

Ready to hang framed print or mounted on Alu-Dibond base sealed under acrylic glass is also available, contact Artfinder for details and price

*NOTE - All images used are an approximate scale for illustrative purposes and individual artwork scale may differ. Always check the artwork dimensions and measure your room carefully.

Materials used:

Hahnemühle FineArt Pearl paper (285 g/m²)

Tags:

#abstract #colourful #pastel #pattern #photography #architecture #fine art #people #geometry #documentary14 day money back guaranteeLearn more